F13 A3+ DTF Printer with Curing Oven: Advanced Direct-to-Film Printing Solution for T-Shirts and Textiles High-Quality Textile Printing Machine for Professional Customization

F13 A3+ DTF Printer with Curing Oven: Advanced Direct-to-Film Printing Solution for T-Shirts and Textiles High-Quality Textile Printing Machine for Professional Customization

Share

Couldn't load pickup availability

Procolored A3+ R1390 DTF Printer with Curing Oven

About This Item

The Procolored R1390 DTF Transfer Printer is a professional-grade, easy-to-use solution for direct-to-film printing. This versatile printer produces vibrant, high-quality prints for various fabric types, including cotton, polyester, blends, and more, on both light and dark textiles.

Features:

-

Versatile Film Usage:

- Supports both roll film and sheet film for flexible printing needs.

-

High Print Resolution:

- Delivers detailed prints at 1440*1440 DPI for superior quality.

-

Vivid Colors:

- Equipped with a minimum ink drop size of 1.5pl and 540 nozzle holes for sharp and vibrant results.

-

Preheating Function:

- Includes preheating to ensure optimal ink drying and prevent ink flow issues.

- Baking temperature: 35-40°C for efficient ink curing.

-

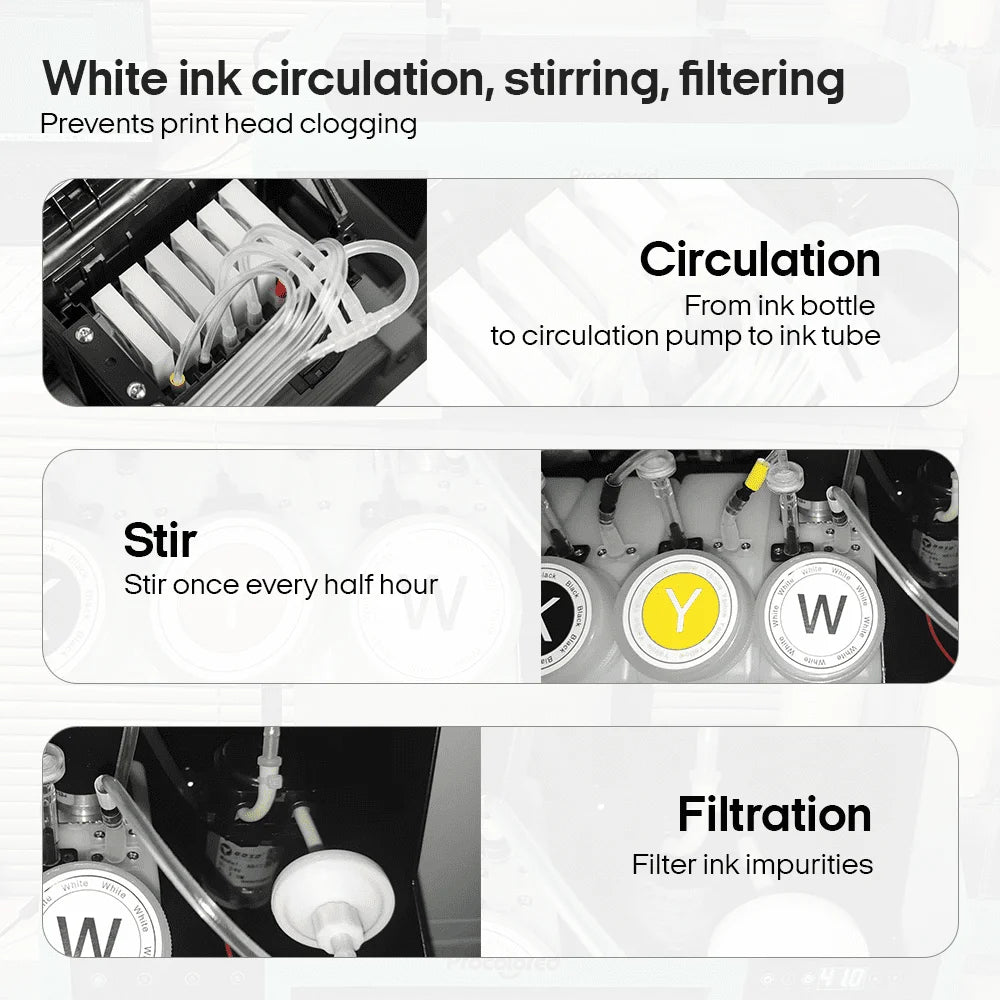

White Ink System:

- Features stirring, circulation, and filtration systems to enhance white ink performance.

- Prevents print head clogs, ensuring durability and smooth operation.

-

Efficient Printing:

- Prints A3 size in 7-8 minutes.

- Ink consumption: 20ml per square meter.

- Supports simultaneous printing of multiple images.

-

Large Print Area:

- Capable of printing patterns up to 13x30 inches in one go.

-

Durable Prints:

- Washable and stretchable designs maintain their integrity even after repeated stretching or washing.

-

Integrated Tray Cutter:

- Prints can be cut directly from the film without manual cutting for added convenience.

-

Automatic Cleaning:

- Supports automatic cleaning with a simple press of F12 using RIP software.

-

RIP Software Compatibility:

- ProRip software allows importing and adjusting multiple images for efficient batch printing.

-

Heating Functionality:

- Built-in heating function ensures proper ink drying and adhesion.

-

Robust Warranty:

- Print head warranty: 3 months.

- Accessories unrelated to ink: 36 months.

Specifications:

- Model: DTF-1390

- Print Precision: 1440*1440 DPI

- Print Speed: A3 format (1440 DPI in 7 minutes)

- Ink Consumption: 20ml per m²

- Ink Supply Mode: 6 colors (CMYK+WW)

- White Ink: Supported with stirring, circulation, and filtration systems

- Print Media: Leather, textiles, and more

- Print Width: 330mm (13 inches)

- Software: ProRip

- Operating System: Windows

- Weight: Net: 20kg; Gross (with oven): 38kg

-

Dimensions:

- Device: 800330215 mm

- Package (with oven): 843848 cm

- Voltage/Plug: Varies by country

What’s in the Box?

- ✅ DTF A3 Printer

- ✅ Curing Oven

- ✅ 100M PET Film (30cm x 100m)

- ✅ Initial Ink (CMYKW 250ml x 5)

- ✅ ProRip Software

- ✅ 500g Hot-Melt Powder

- ✅ Additional Accessories

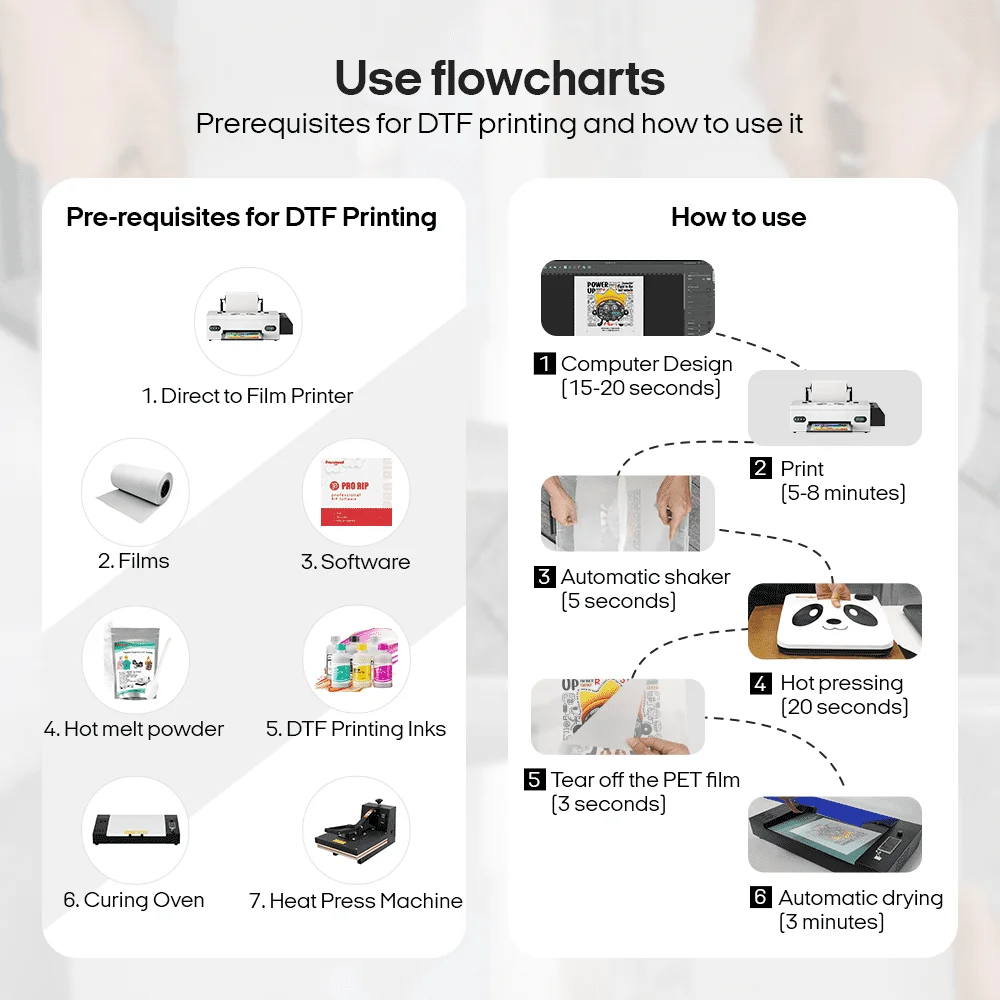

DTF Printing Overview

What is DTF Printing?

Direct-to-Film (DTF) Printing involves printing designs on a special film and transferring them directly onto fabric. It works seamlessly with a wide variety of fabrics, including cotton, polyester, silk, rayon, and more.

Pre-Requisites for DTF Printing:

- DTF Printer: Procolored R1390 or equivalent.

- Films: Roll or sheet films.

- Software: Compatible RIP software.

- Hot-Melt Adhesive Powder: For transferring designs to fabrics.

- DTF Inks: High-quality inks for durable prints.

- Curing Oven: For proper ink curing.

- Heat Press Machine: Final step to transfer designs onto textiles.

This printer is perfect for creating washable, stretchable, and high-color fastness designs, making it an excellent choice for professional and custom apparel printing.

With preheating function

drying ink to avoid the flow of ink

Baking temp: 35-40 degrees

ultra fast printing

A3 size, need to print 7-8 minutes; consume 20ml ink per square meter

To improve the white ink printing and lower the risk of clogging printhead, we have newly designed a system including stirring, circulation, and filtration systems, which can greatly improve the activity of white ink, make the effect of white ink the best, and reduce the risk of print head clogging, so that the machine can continue to run well and prolong the service life of the machine

White color at the same time;

white ink and color ink can be printed at the same time to improve printing efficiency

A3 curing oven for DTF

Upgraded oven, heating up faster. Add smoke filtering function, no need to buy filters; add film suction cup to prevent hot hands.